Double Inlet Double Width Blower - DIDW

DIDW centrifugal blowers are designed for high volume, low pressure, low noise level for Air Conditioning, General Ventilation, Air Cooling, pressurization and wherever Air Draft over large areas is needed. The welded construction makes the fan robust and sturdy. Impellers are statically and dynamically balanced.

Single Inlet Single Width Blower - SISW

Material handling for most industrial requirements : In view of this high efficiency fans (SISW) are a new concept in material handling.

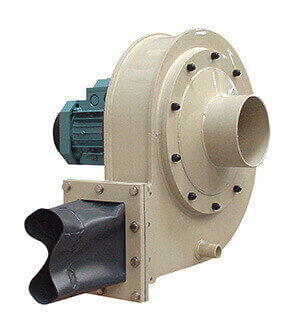

High Pressure Blower / PA Fan

Application: For combustion air in foundries / furnaces, glass cooling, during chips, smoke abatement conveyance of gases/material.

Medium Pressure Blower / FD Fan

Low Pressure Blower / ID Fan

Material Handling Blower

D. C. Motor Blower

DIDW centrifugal blowers are designed for high volume, low pressure, low noise level for Air Conditioning, General Ventilation, Air Cooling, pressurization and wherever Air Draft over large areas is needed. The welded construction makes the fan robust and sturdy. Impellers are statically and dynamically balanced.

Barrel Cooling Blower

When air ventilation is dry and hot and process conditions need some degree of cooling and humidity for the process to work and humans to get some level of comfort this type of water base cooling.

Centrifugal Blower

TRIM Suction

Cleantek Manufacturing Paper Trim Removel Suction System with High vaccum Ventury Unit. This Product is Very Usaeful in Paper, Printing, Foils, Granule & packaging Industries. Available in Various Capacity as Per Customer Requirements.

Root Blower

The Standard Package is single stage arrangement. Rgid Common base makes the package run at least vibration. special motor base gives the most possibility for diffrent motor size and make the motor alignment very easy . Two stage Models are available on request for pressure over 1kg/cm2.

The standard package is single stage arrangement. Rigid common base makes the package run at least Vibration. Special motor base gives the most possibility for different motor alignment very esay. Easy for maintenance and vacuum tank cleaning.